NSF10 monitor uses force-displacement real-time curve to detect and evaluate product quality and production

process to ensure assembly quality and achieve defect-free production of assembled parts.

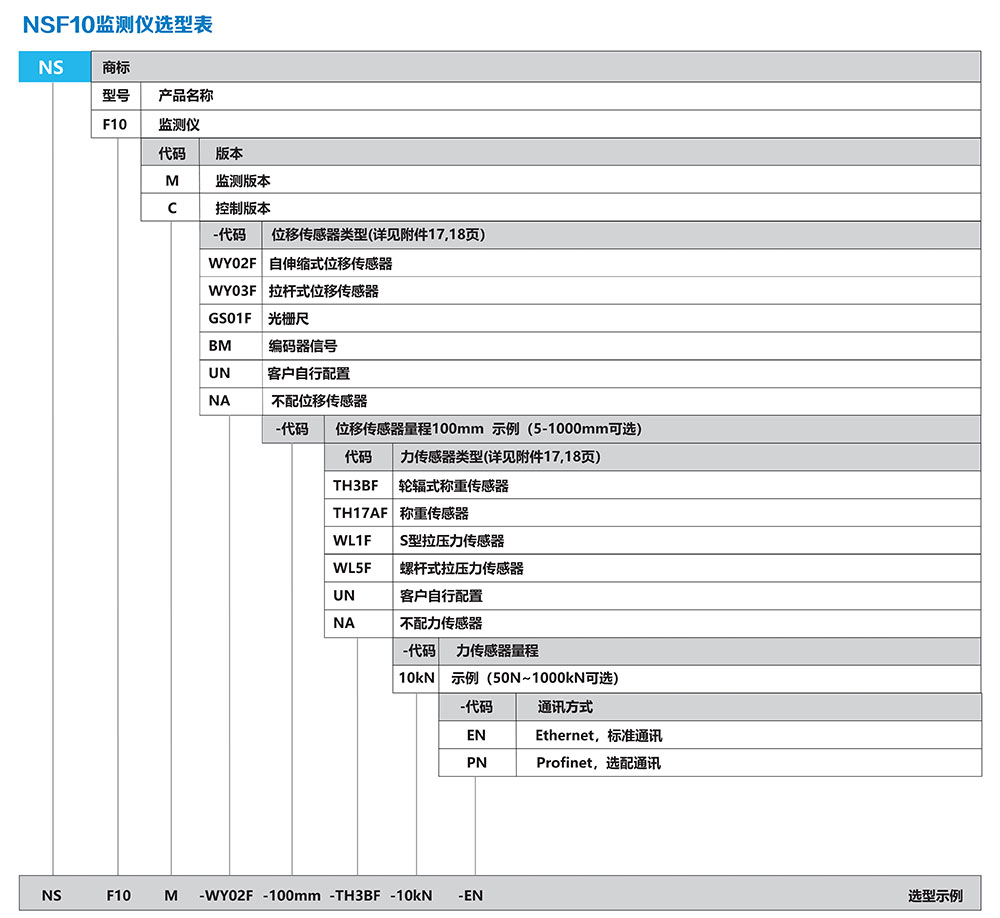

The NSF10 monitor has a variety of force-displacement sensor input interfaces and monitoring graphic display functions.

to meet the needs of different monitoring tasks.